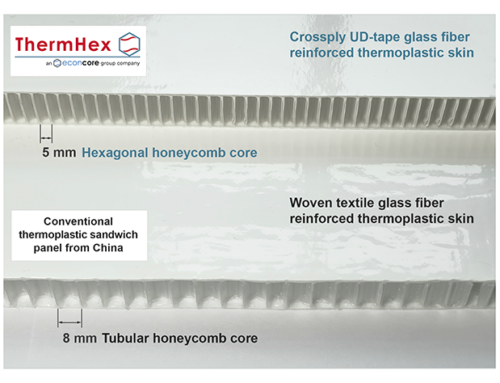

Who invented it? The bees. It has been known for centuries that honeycombs are extremely stable and light due to their geometry. No wonder that this honeycomb structure, modeled on materials, has long been used in industry. Especially where low weight and rigidity are important, such as in aircraft construction or more recently in the rotor blades of wind turbines.

Halle has been the production location for such trend-setting thermoplastic honeycomb core materials since Monday. And on a large scale. ThermHex Waben GmbH has invested around 1.5 million euros in its new company headquarters in Merseburger Straße, which will be inaugurated by the Minister of Agriculture Reiner Haseloff (CDU) on Monday.

As Managing Director Jochen Pflug explains, around one million square meters of honeycomb material are to be produced here every year, and six jobs have been created. “Contrary to conventional processes, we have significantly improved the technology of honeycomb core production,” says the 41-year-old engineer for aerospace engineering. At the Belgian University of Leuven, where he studied fiber and composite technology, he worked intensively on this subject.

The amazing thing: “The basics of the technology to which Pflug is now connecting were originally developed in Halle – by the luxury paper goods factory“ Heilbrun & Pinner ”. The company, which had its headquarters in Geiststrasse, created the process for the production of decorative honeycomb paper in 1901, he reports.

Halle’s products, including decorative cards, were exported to the USA and Great Britain. He rediscovered those patents that demonstrated the innovative strength of the Saale industry during a research project at the Belgian university.

“Our approach was to combine this technology from the packaging industry with the conventional process for the production of honeycomb cores,” said the engineer. As a result, plastic sheets can now also be used in the packaging industry to produce materials and save energy and at a higher speed than lightweight materials. Plow speaks of around 30 percent less material consumption compared to conventional production methods. The market leaders for double wall sheets from Japan and Italy are already licensees of ThermHex honeycomb technology. “This structure enables minimal use of materials. This is a cost advantage and saves our resources,” says the materials scientist. With cheaper manufacturing costs, the material is becoming more and more interesting for new areas, such as the furniture industry. And: “The thermoplastic honeycomb cores are completely recyclable,” plows points out the ecological aspect.

Pflug has been the managing director of the Belgian company EconCore, a public limited company that deals exclusively with research and development, since 2005. The main shares of this company are held by “EconHP Holding GmbH” from Halle. Thanks to the advice given by the university founding network “Univations” and the positive funding applications – 50 percent of the investment is borne by the state – Jochen Pflug has decided to produce in Halle in the future.

But that’s not the whole truth. A location factor that should not be underestimated was love. “My wife also happens to come from Halle,” reveals the managing director.