More efficient sandwich panels

More efficient sandwich panels thanks to a combination of cores

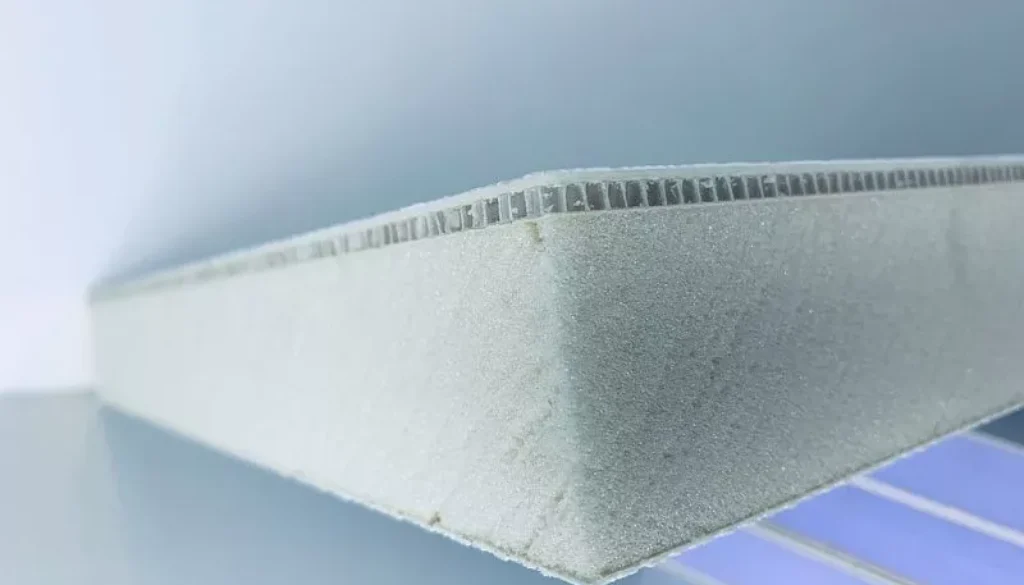

PANEELtec ordered honeycomb cores from ThermHex for the first time at the end of 2012. Since then, the partnership and demand for honeycomb cores has grown steadily. One of PANEELtec’s most requested products is the Duo-Core, which consists of a ThermHex honeycomb core and a foam core. By using the thermoplastic honeycomb core from ThermHex, PANEELtec has been able to reduce the weight by 10% and improve the properties of the panels. The cores are used for the production of sandwich panels for major commercial vehicle and trailer manufacturers in Germany, Austria and the Netherlands. Sales of the honeycombs increased by 47% in 2020/21 compared to the previous year.

The panels are mechanically more stable, whereby a honeycomb core can also be used without any problems with a panel thickness of 20 mm. Under mechanical stress, the cells of the previously used PU foam are destroyed, so that bubbles can form under the GRP cover layers.

With a 20 mm full honeycomb panel, this risk does not exist at all, but this panel also has no insulating effect. If both insulation and mechanical strength are required, the Duo-Core or Triple-Core is the best choice.

The combination of insulation and mechanical strength in PANEELtec’s Duo-Core is achieved by adding a foam core to a 3.5 mm honeycomb core. The result is a panel in which the mechanical load is transferred to the surface, thus fully preserving the cells of the foam. These properties are further improved with the triple-core product, which also uses honeycomb technology.

Jürgen Schmidt, Managing Director of PANEELtec, says: “Every gram of weight that we can remove from a trailer, motorhome or boat saves energy and money. With ThermHex honeycomb cores in our Duo-Core panels, we achieve a weight saving of 10%, and that’s money in our customers’ pockets and good for the environment. It also offers other benefits such as stiffness, durability and strength.”

Dr. Jochen Pflug, CEO of ThermHex honeycomb, says: “Light weight and durability are fantastic properties for automotive panels. The higher compressive strength of the additional honeycomb core enables a reduction in cover layer thickness and foam core density. We are delighted that our honeycomb cores enable PANEELtec to offer such innovative products.”

PANEELtec produces sandwich panels using a vacuum bonding process. This enables the production of large-format, lightweight, stable and, depending on the combination of facings, cores and inserts, highly functional panels. The universal, lightweight insulating panels have a wide range of applications in a wide variety of industries.

The polypropylene (PP) honeycomb cores from ThermHex are used wherever an optimum strength-to-weight ratio is required. These include automotive, boat, yacht and shipbuilding, interior design and furniture, construction, wind and solar energy, swimming pools, prefabricated bathrooms and others.

ThermHex Waben uses green electricity for the production of its honeycomb cores, as the electricity comes from renewable energy sources. The processing and monitoring of the green electricity supply is certified in accordance with TÜV SÜD CMS Standard 92. This guarantees reliable and traceable procurement, balancing and supply of electrical energy from renewable sources.

ThermHex Waben GmbH started production in Halle (Saale) in 2010 and is a licensee of EconCore NV (Belgium), the technology leader for the cost-efficient production of sandwich materials.