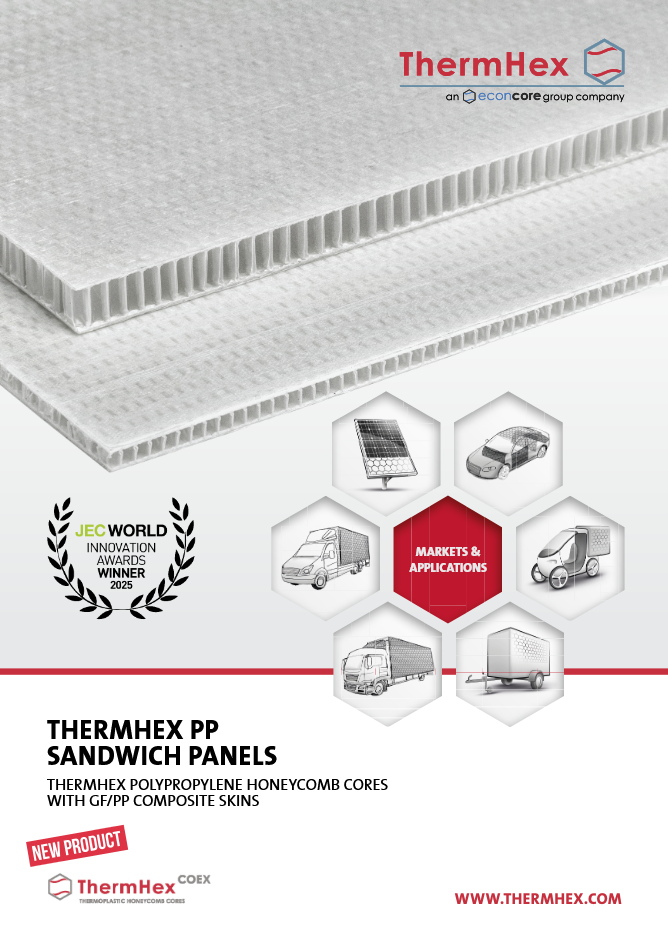

Thermoplastic sandwich panel with PP honeycomb core and glass fiber/PP-skins

Advantages:

- Weight savings of up to 80% compared to monolithic material possible

- Major cost reduction

- High bending stiffness

- High compressive and shear strength

- Energy absorbent / impact resistant

- Resistant to moisture, acids and bases

- Easy and resource-friendly converting

- Green and easily recyclable solution

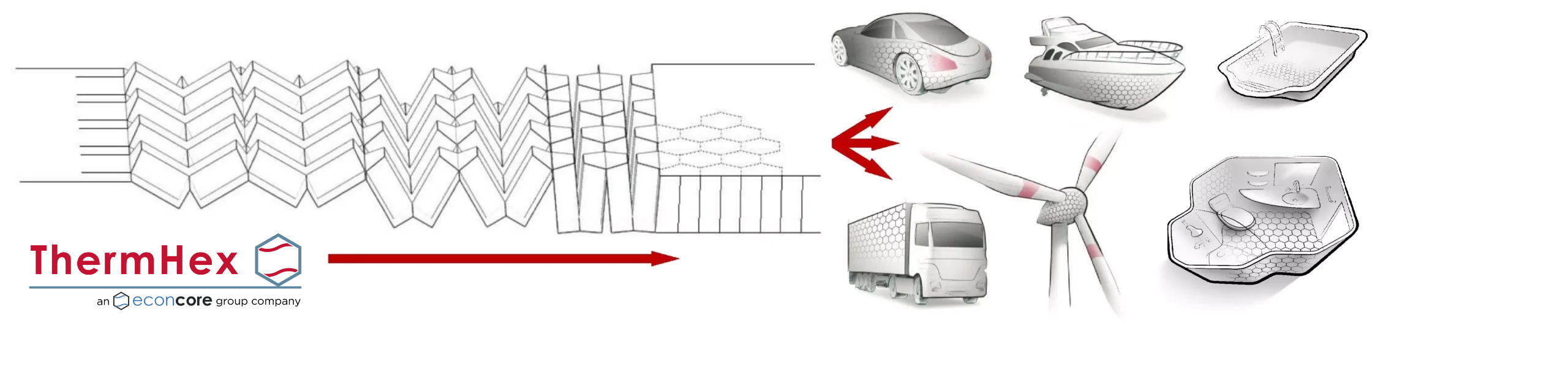

The PP honeycomb sandwich panel is a semi-finished panel that consists of two thin skin layers of fiber reinforced thermoplastic composites (organosheet) spaced by a thermoplastic honeycomb core to provide high stiffness at minimal weight, without the need of incorporating additional stiffening ribs as often required for parts based on monolithic organosheet.

The PP honeycomb panel is particularly cost efficient as it is made in a continuous process: the skin layers are applied in-line and welded to the honeycomb core as it is produced.

In further production steps, especially with regards to the automotive industry, this organosandwich can be further processed into final parts and functionalized within very short cycle times. A typical conversion method is compression molding whereas the functionalization can be realized by integrated injection over-molding.

The PP honeycomb panel is ideal for large series production of components for the automotive industry and many other applications, where the performance, light-weighting and cost-efficiency need to meet together.

These applications include: automotive trunk floors and underbody panels, mini-van and minibus floors, cladding and racking, panelling in trucks and trailers, cargo boxes in last mile delivery vehicles, including cargo bikes and electric vans, panelling in recreational vehicles, industrial shelving, and many more. The panels are often used to replace plywood and many other conventional monolithic and sandwich panels.

Click here to find out more about the EU-funded joint research project, Organosandwich.