Future aircraft cabins – where lightweight meets sustainability

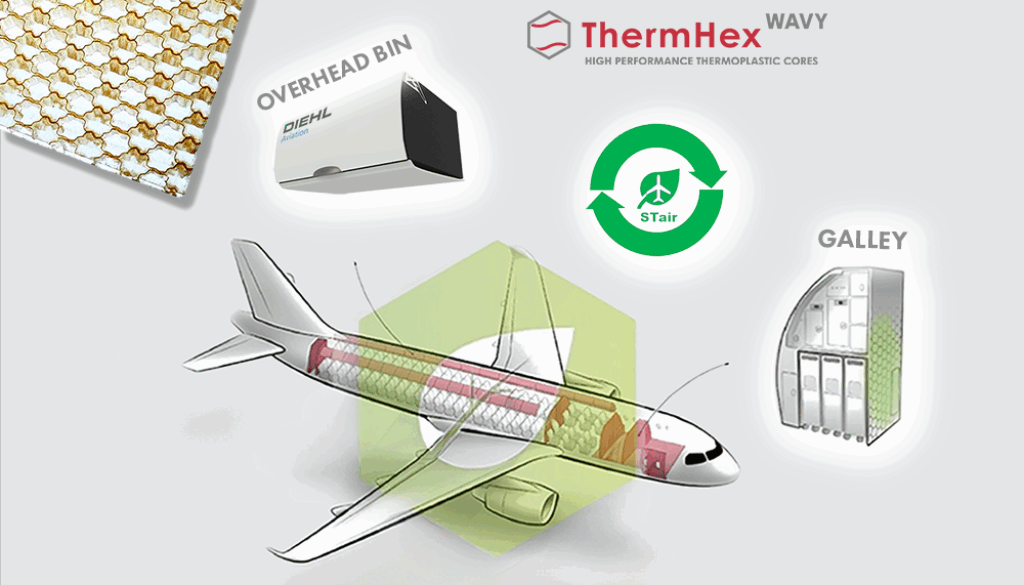

Within the STair project (2025-2027) ThermHex Waben is currently working together with it’s partners Fraunhofer Institute for Microstructure of Materials and Systems IMWS, Diehl Aviation and Ensinger GmbH to develop cabin components based on recyclable, thermoplastic sandwich structures. These thermoplastic sandwich materials offer major advantages: they are significantly lighter, enable faster and more energy- and material-efficient manufacturing, and provide improved recycling options compared to conventional thermoset solutions.

The innovation lies in the potential to shred panels and repurpose them into new components like clips and inserts. By using PEI (Polyetherimide) with a fiberglass deck layer, these parts can be melted and reformed into useful structural elements – extending the lifecycle of the original material and reducing waste. And there’s another advantage: material compatibility. Since the clips and the panel are made from the same base material, welding them together becomes easier and more reliable. This not only simplifies assembly but also enhances the strength and integrity of the finished product, which is crucial for demanding applications like Aerospace and Mobility. One of them is shown in the picture: Supplier Diehl Aviation recently won the coveted Crystal Cabin Award for its ECO Bin.

In a nutshell, ThermHex Waben GmbH’s approach within this project

✅ leads to a longer lifespan for their honeycomb sandwich panels than many materials currently used in aircraft mobility.

✅ All of this is achieved without compromising performance,

✅ proving that sustainability and strength can go hand in hand.

By reducing component weight, lowering fuel consumption and CO2 emissions, ThermHex takes a meaningful step toward a circulare conomy. This shift not only reduces waste but also conserves resources and lowers the environmental burden of new production, and by this contribute to circular economy principles – supporting a more sustainable future in aviation. With STair, the involved project partner aim to demonstrate by 2027 that thermoplastic sandwich lightweight technology is ready for real-world aviation applications – from overhead bins to sidewall panels and other interior components. ThermHex Waben is looking forward to continue the dialogue together with it’s partners for shaping the transition toward greener air travel together.