The importance of lightweight materials is increasing steadily, especially in automotive industry. Experts see lightweight construction materials as a requirement for cost-efficient and competitive e-mobility.

Take it Lightly: The Honeycomb Core

Where lightweight construction is required, sandwich panels are the ideal solution. By using a lightweight honeycomb core material that keeps two thin skin layers apart, higher rigidity and strength can be achieved with less material than with only one monolithic material. The result is significant weight savings of up to 80 percent, plus considerable potential for material cost savings. An advantage that the automotive and transportation industry knows how to benefit from: for example, the walls or floors of modern truck bodies and trailers usually are lightweight sandwich panels consisting of a thermoplastic polymer-based core and skin layers of fiber-reinforced plastics. Manufacturers of cars for end customers are also following in the footsteps of lightweight automotive components. ThermHex Waben GmbH from Halle/Saale in Germany produces and delivers the right product for them.

Honeycomb Cores “Made in Germany”

ThermHex offers automotive manufacturers and parts suppliers recyclable thermoplastic honeycomb cores made of polypropylene as a strong, yet flexible lightweight material.

The ThermHex core production is divided into four main process steps. The first step is the film extrusion of a thin thermoplastic foil, in this case made of polypropylene. Thereafter, the thermoplastic film is formed by a vacuum deep drawing process with special forming rollers to half open honeycomb cell rows. Immediately after thermoforming the cell rows are folded to honeycomb cores. In the last process step, the folded honeycomb cores are laminated by contact welding in a double belt press. At the end of the production line, the panels are cut to the length according to the customer’s requirements.

The standard volume weight is 80 kilograms per cubic meter. A lighter core with a density of 60 kilograms per cubic meter is also suitable for applications with lower demands on compressive strength. Whereas for applications that require a higher density also core material with volume weight of 120 kilograms per cubic meter is available. The thickness of the honeycomb cores ranges from 3 to 30 millimeters and the cell sizes from 3 to 9.6 millimeters. The ThermHex honeycombs have a half-opened surface, which, in combination with various surface finishes enables an optimal connection between core and skin layer in the subsequent sandwich element which is essential for the mechanical performance. Small cell sizes also enable an almost perfect surface quality.

This worldwide patented continuous in-line process, in which various skin layers can be directly applied to the honeycomb core, is the best way to produce sandwich panels at competitive cost. This is because other processes require each layer of honeycomb to be individually cut from a block and then laminated. Finally, ThermHex customers process the honeycomb panels into e.g. 3D-shaped functionally integrated components, for example by edge trimming, thermoforming and injection molding.

A Samba with Honeycomb Core

One customer is the automotive supplier DPA Moldados. The automotive parts manufacturer from Itupeva in the Brazilian state of São Paulo has been developing and manufacturing molded parts for over 20 years, which are used as interior trim components, air ducts or thermal and acoustic insulation for various types and brands of cars. DPA Moldados is committed to using innovative and sustainable materials and products. The supplier stands out from the competition mainly because he is able to produce molded parts in a very cost-efficient way and in one piece. DPA Moldados also recognized early that car manufacturers need alternatives for various monolithic components which are lighter and stronger but still meet the price requirements.

The company has found the solution in the form of sandwich construction with the thermoplastic honeycomb core made in Germany. Over the next few years, more and more components will gradually be produced in this way. Since May 2017 the Brazilians have been using the black version of the polypropylene honeycomb core from ThermHex. It replaced the previously used paper core materials of other producers. The thermoplastic recyclable material combination with the ThermHex core is more cost-efficient while having the same or better performance, and the production process needs less energy which also lowers the production costs and environmental impact. The honeycombs are used, for example, as the core structure in the trunk floor of Hyundai Creta ix25. Preheated glass fiber/polypropylene skin layers are applied around the honeycomb core and then all the individual materials are combined and pressed in one step into a ready-to-use sandwich component. According to DPA Moldados, the company is currently one of the few manufacturers in the world that is technically capable of producing this type of sandwich molded part for mass production.

Advantages with Organosandwich

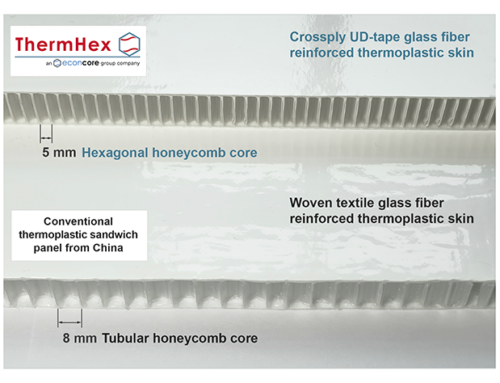

Besides the production of the core material and due to the production process and the possibility to include the lamination of skin layers directly after folding of the honeycomb core the company ThermHex is now also producing a sandwich panel named Organosandwich, dedicated primarily to the automotive industry as well as other highly automated industries. While an offline pressing process allows a lamination of different types of top layers to the core, it is also proven, that monolithic organo-sheets can be laminated inline to the folded honeycomb core in the last step of the ThermHex process. This enables the continuous production of Organosandwich semi-finished products.

ThermHex laminates UD tapes made of glass fiber-PP directly onto the core. The continuous production of the core and the in-line lamination of the skin layers makes the panel material much more economical than sandwich structures with conventional core materials. In comparison to a monolithic FRP laminate, a sandwich structure of the same stiffness requires a lower number of layers, which leads to considerable cost savings when using FRPs containing carbon or glass fibers. In this way additionally to the weight saving, material cost savings are possible.

Due to the thermoplastic matrix, the Organosandwich semi-finished products subsequently offer the possibility of being processed into complex sandwich components by hybrid injection molding. Here, the semi-finished sandwich products can be thermoformed into curved shell structures. Furthermore, it is possible to integrate different joining elements on the component, which are necessary for system integration but also for joining with individual components.

With the ThermHex honeycomb core and the Organosandwich, the weight of automotive components can be significantly reduced compared to solid materials, while maintaining the same or even better strength. The results are that automobile brands can offer electric vehicles with a greater range at lower prices, car users can save battery power and commercial vehicle drivers profit from larger payload capacity. Due to the weight reduction of the conventional vehicle, the fuel consumption is also lower which helps to reduce the CO2-footprint. So, everyone can benefit.

Honeycomb Core as Allrounder

In addition to the production of automotive components, ThermHex honeycomb cores are also used for other applications, among others the largest British commercial vehicle producer uses the ThermHex core for their truck box bodies. Other customers use the core for the interior design of boats, for the production of modern swimming pools, prefabricated bathrooms, for furniture manufacturing or in wind turbine blades and the number of applications is increasing steadily.

The production process is offered worldwide under license by the Belgian mother company EconCore and is used, for example, by Renolit for the trunk floors of the Maserati Ghibli and Jaguar F-Type. In Japan, the technology is marketed by Gifu Plastics and used for interior parts of the Toyota Prius.

Published online on reinforced plastics on May 27, 2020