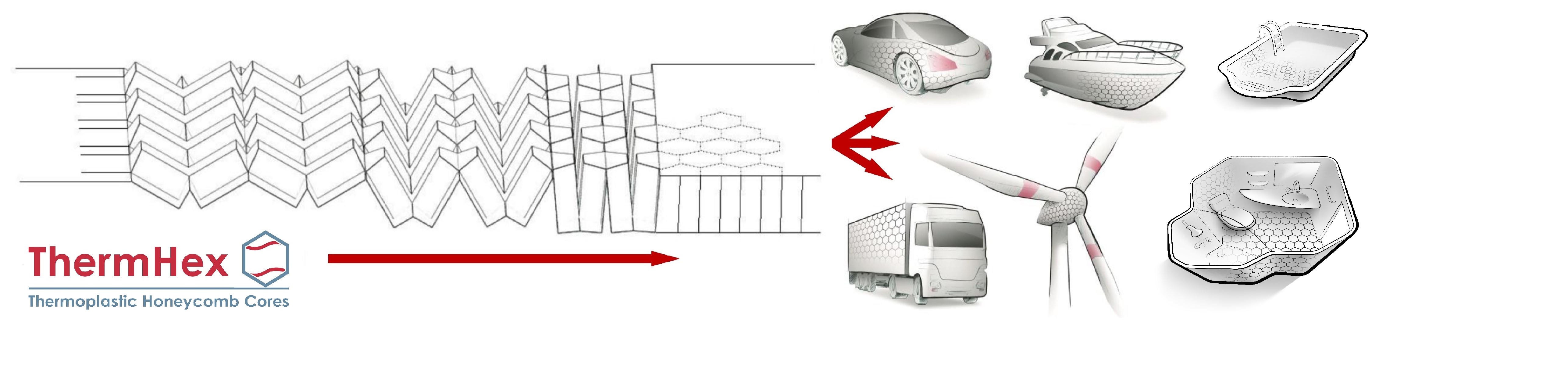

ThermHex production process

The patented ThermHex technology enables the production of thermoplastic honeycomb cores for the first time in a continuous production process.

The honeycomb core is produced in a continuous in-line production process by, successive, extrusion of a flat PP-film, thermoforming, folding and in-line lamination of the surface finish (e.g. closure film and PET non-woven). The ThermHex honeycombs have a half-closed surface which allows an optimal connection between the core and the cover layer material.

The ThermHex honeycomb cores can be produced directly from the extruder or from a film roll, which further improves the flexibility.

The ThermHex technology enables the cost-optimized production of honeycomb cores from very different thermoplastic materials. Cell sizes, material densities and honeycomb core thickness can vary according to requirements.

The integration of the ThermHex honeycomb production into an existing production process for sandwich panels or special lightweight components into a continuous production leads to further cost reductions and improved product quality.

We are an EconCore licensee:

ThermHex Waben GmbH manufactures its products as a licensee of EconCore NV, Leuven (Belgium). Further information is available on the Internet www.econcore.com or by calling +32 16 38 10 60

Please visit: www.econcore.com