Composite Sandwich Conference - CSC 2022: global experts present latest developments

Over 100 composites and sandwich construction experts from around the world have spent two days exploring the technical challenges of how to strip weight from transport using honeycomb cores. The experts attended the joint Thermhex and Fraunhofer IMWS Composite-Sandwich Conference held in Halle (Saale) at the end of May (24 – 25 May 2022).

The delegates were shown the latest research, covering a wide range of areas, including among others:

- Principals of sandwich technology for airframe and interiors;

- Thermoplastic sandwich composites – novel processing in automotive;

- The design of composite sandwiches for train car body shells;

- Automated fibre placement for sandwich parts in helicopters;

- Multi-scale modelling and the future of the composite sandwich technology.

The conference provided the opportunity for engineers and scientists from across the composites sector to explore new fields of application and network with some of the leading minds in the sector.

The construction of sandwich materials, based on fibre-reinforced plastics, enables highly efficient lightweight structures and is making an enormous contribution to resource conservation in a large number of industries. Using sustainable sandwich material reduces not only weight but at the same time the CO2-footprint.

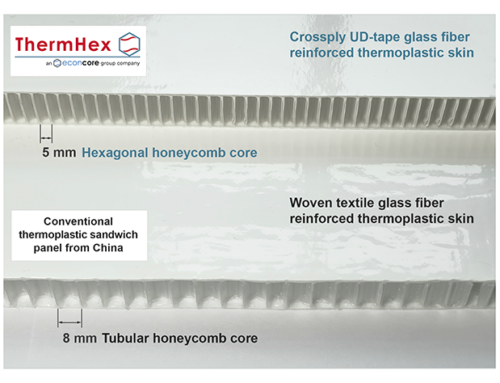

Composite sandwich materials are used where an optimum strength to weight ratio is crucial. ThermHex Waben’s polypropylene lightweight sandwich panels have been used in the manufacture of trucks, ship interiors, prefabricated bathrooms and modern swimming pools.

Dr Jochen Pflug, CEO of ThermHex said: “Honeycomb sandwiches are gaining increasing usage in a wide range of industries. I am constantly amazed with the creativity of the industry in applying this technology, efficiently and effectively and excited about the future applications and potential of composite sandwich materials.”

“The conference enabled a very productive exchange and brought many new insights, for example on the need for cost-efficient composite sandwich structures and their processing by automated production methods, the reliability of the components produced with them, or even new possible applications for sandwich technology”, summarizes Dr. Ralf Schlimper from the Fraunhofer IMWS. “The very positive response shows how huge the potential of the technology and the interest among companies is, especially in the field of mobility systems, to tap into it.”

The keynote speech of Professor Axel Herman of CTC Stade, an Airbus company and the University of Bremen to open the conference at the German National Academy of Sciences Leopoldina was given be Tassilo Witte. Other speakers came from some of the leading companies across the industries, including Beyond Gravity (formerly Ruag), Airborne, Elring Klinger, Engel, Fraunhofer IGCV, Fraunhofer IMWS and Econcore.

Delegates were also able to visit ThermHex Waben’s production facilities and the Fraunhofer pilot plant Centre for Polymer Synthesis and Processing PAZ to get an insight view of the potential of efficient production technologies for thermoplastic sandwich structures from ThermHex’s semi-finished Organosandwich products to 3d formed and functionalized parts via Fraunhofer IMWS’s TS-Moulding Technology.