Handling of core material – ThermHex Honeycomb Cores

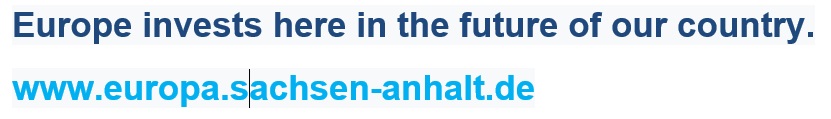

Bonding of skin layer and honeycomb core

During bonding of the ThermHex honeycomb core it is essential to use the right adhesive. The adhesive is significantly determined by the requirements of the sandwich compounds.

Laminating the skin layer onto the honeycomb core

ThermHex honeycomb cores can be laminated with different methods for example hand lay-up with vacuum molding, fiber resin spray-up, vacuum or light-rtm. Possible types of resin are polyurethane, polyester, epoxy or phenol.

Spray-up

For large components or lamination of ThermHex honeycomb cores the fiber resin spray-up suits well. During this process, the merging of the compounds (resin, reactant and reinforcing fiber) as well as the deposition are done with a fiber-resin diffuser.

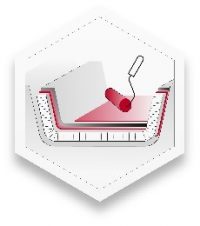

Forming of honeycomb cores

Besides forming with heat it is also possible to form honeycomb cores of small thickness (e.g. 3.5 – 10mm) at room temperature during curing of the skin layers with the help of pressure or vacuum.

Cutting of honeycomb cores

The cutting of ThermHex honeycomb cores is carried out with conventional tools and methods such as e.g. circular saw, circular knife, waterjet cutting, laser cutting, punching and so on.

Edge closure and load application

Depending on the kind of procedure, usage and pressure on the finished sheet different edge closures are possible. For load application points, it is recornmended to work with inserts that connect the two skin layers, in order to achieve a higher load application.