The use of fibre-reinforced plastics in sandwich construction enables highly efficient lightweight structures. Leading international experts presented and discussed current trends in material and technology development as well as new fields of application for sandwich materials at the “Fibre Composite Sandwich Conference” in Halle (Saale) on 24-25 April. They presented solutions in the field of tension between raw material efficiency, digitalisation and sustainability, for example for applications in the automotive industry, aviation or photovoltaics.

The conference was jointly organised for the third time by ThermHex Waben GmbH and the Fraunhofer Institute for Microstructure of Materials and Systems IMWS and attracted more than 100 international guests from industry and research to Halle (Saale).

Ignaas Verpoest, Professor Emeritus of the Composite Materials Group at the Catholic University of Leuven, opened the conference with his keynote speech “Innovations in composite sandwich structures: reflections on a personal journey”. Looking back over more than 30 years, he showed that in addition to creative inventions, a deep understanding of material interrelationships, the development of experimental methods and virtual models and, last but not least, a focus on the needs of industry are decisive criteria for successful material innovations.

On the second day of the conference, a number of sessions focused on current R&D solutions for the consistent implementation of lightweighting approaches using sandwich construction and sandwich core materials. Here it became particularly clear that these can score triple points in terms of sustainability: They often enable production processes with significantly lower material consumption than monolithic construction. Thanks to their lightweighting potential, they can help reduce emissions during their service life, for example by reducing the weight of vehicles. At the same time, thermoplastic mono-material sandwich components offer significant advantages in terms of end-of-life recyclability compared to thermoset fibre composite components.

»The presentations and discussions with our guests highlighted the importance of balancing material performance and cost. Many current developments and research projects are already addressing this relationship. I was also impressed by the wide range of applications and material solutions presented, from plastics to ceramics and wood.«

says Dr Ralf Schlimper, who chaired the conference on behalf of the Fraunhofer IMWS.

»I am delighted that we have once again been able to welcome such a high-calibre and large audience. The variety of industries represented here underlines the enormous potential of sandwich construction for industrial applications.«

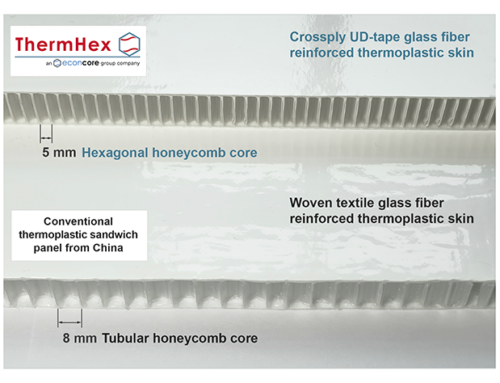

says Jochen Pflug, Managing Director of ThermHex Waben GmbH and organiser of the conference. During the conference his company presented for the first time the new product »ThermHexWAVY«, a thermoplastic honeycomb core with a wave-shaped cell wall geometry, which allows a significant increase in compressive strength. The special geometry can be produced with any thermoplastic polymer on existing ThermHex production lines.

Other innovations presented at the Composite Sandwich Conference included applications of sandwich technologies in helicopter structural components (Airbus Helicopters), as protective structures in the underbody of electric vehicles (Audi AG) and as aerodynamic underbodies for sports cars (Porsche AG). Another focus was on recyclable thermoplastic core materials with particularly good fire protection properties for aircraft interior components. Evonik Operations presented a polyetherimide (PEI) foam core material based on pre-expanded microgranules, and ThermHex showed a PEI honeycomb core. Solarge demonstrated the potential of sandwich construction for photovoltaic applications, such as ultra-lightweight modules that can be installed on roofs with insufficient load-bearing capacity for standard modules.

»The content of the sessions showed how dynamic the development is and how high the level of activity in the industry is in order to save not only component weight but also material.«

said Pflug at the end of the conference, which included a company and product exhibition and visits to the ThermHex production facility and the Fraunhofer sites in Schkopau and Halle.

»The presentations also highlighted the need for further research, from in-depth knowledge of material properties and material development, to solutions for quality and process control, to efficient ways of reducing the use of thermoplastics in structural applications, to the development of methods for specific designs.«

concludes Schlimper. The next Composite Sandwich Conference is planned for spring 2026.

Dr Jochen Pflug (ThermHex Waben GmbH, left) and Dr Ralf Schlimper (Fraunhofer IMWS, right) organised the conference. Ralf Schlimper (Fraunhofer IMWS, right) organised the conference in Halle (Saale), Ignaas Verpoest (2nd from left), Professor Emeritus of the Composite Materials Group at the Catholic University of Leuven, opened the conference with his keynote speech “Innovations in composite sandwich structures: reflections on a personal journey”, Prof. Dr. Erica Lilleodden (2nd from right), Director of the Fraunhofer Institute for Microstructure of Materials and Systems IMWS, welcomed the conference guests. © Uwe Köhn

See more impressions on the event page: www.composite-sandwich.com