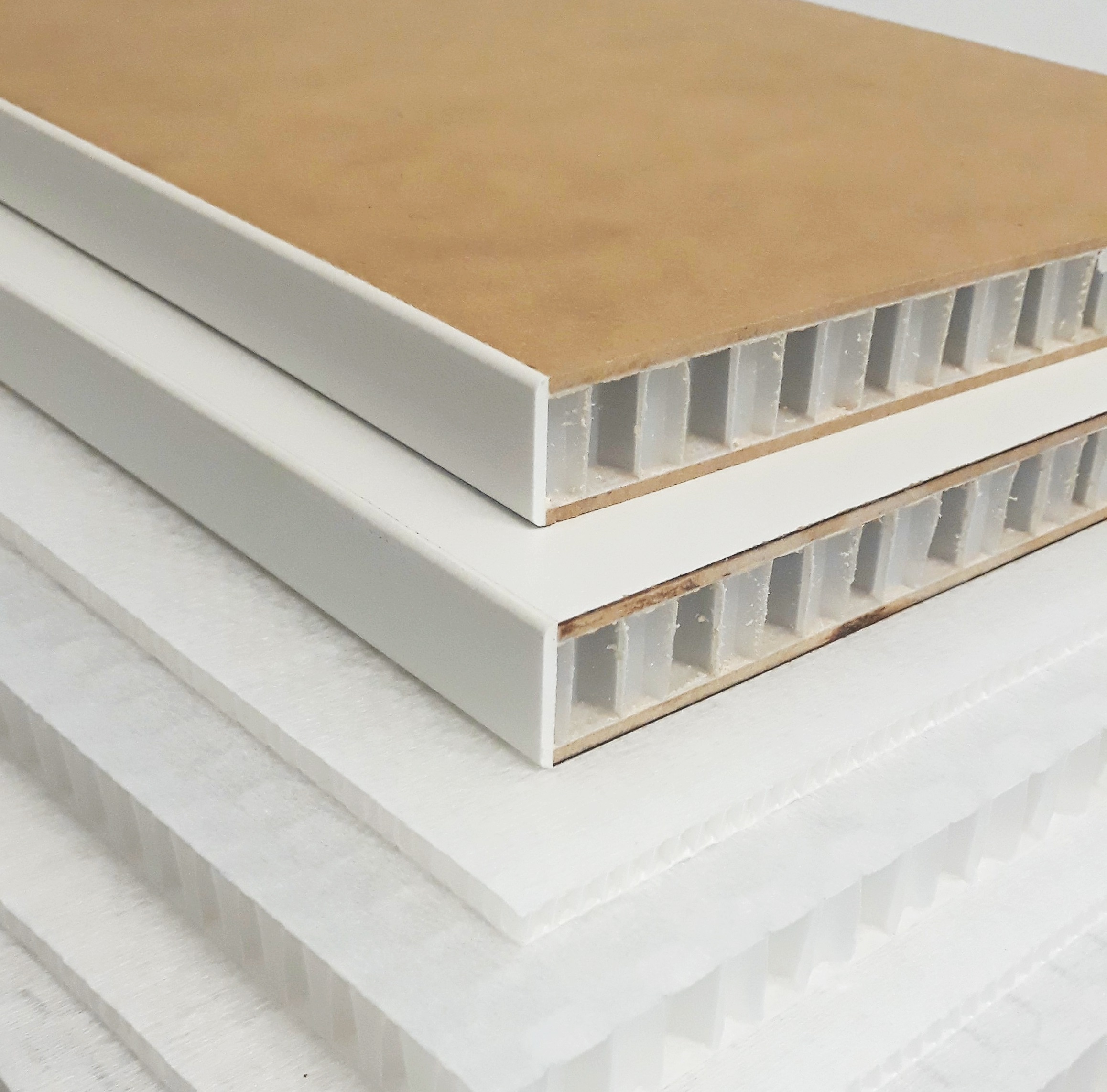

Honeycomb panels “from a single cast” reduce weight and costs

Plastic honeycomb cores for lightweight construction are traditionally manufactured in blocks and then cut from the block panel by panel. This is a very complex process and too expensive for many applications. But ThermHex honeycomb cores are produced differently: they are produced in a world-wide patented in-line production process. In addition to material and weight advantages, this “ThermHex-Process” brings considerable cost savings.

ThermHex polypropylene (PP) honeycomb cores today replace foam, paper honeycombs or solid materials such as pressboard (HDF) or wood. Since the start of production in 2010, the honeycomb panels have proven their worth in furniture, vehicles, boats, swimming pools and other applications. They can also be used in construction industry or for building theatre and film sets.

Typical example for furniture construction

The potentials of the technology can be illustrated by the following application example, which emerged from a development cooperation. A 19-millimetre-thick solid chipboard panel with CPL top layer and ABS edge protection was replaced by a sandwich panel consisting of a 15-millimeter PP honeycomb core, two 2-millimeter HDF top layers and CPL top layers and ABS edge protection (see illustration). The HDF cover layers and PP honeycomb core can be joined using moisture-resistant D3 dispersion glue or PU hot melt. The CPL cover layers and the ABS edge protection were applied using methods commonly used in practice.

Numerous advantages for processors and end-users

The advantage of the sandwich using ThermHex honeycomb cores is clear: It weighs only half of the solid chipboard – with identical strength and rigidity. But it is much cheaper to produce, cheaper to transport and easier to assemble. In addition, it has a better weather and moisture resistance compared to wood-based materials or paper honeycombs. This is an advantage for outdoor furniture or furniture for wet areas.

The PP-sandwich panel shown is usually used in closets, shelves or as a table top. For commercial furniture, bathroom and kitchen equipment and other products in the growing segment of the take-away markets for end-users, solid wood chipboard can be excellently replaced by honeycomb sandwich material.

The continuous in-line ThermHex production process to produce honeycomb cores enables efficient production. The otherwise usual intermediate steps, such as cutting from a honeycomb block are not necessary. This results in an enormous cost reduction. On top of this, any material left over during production is completely returned to the production cycle and thus makes the honeycomb core product very resource friendly.

Innovation as the basis for success

ThermHex’ latest product is a high performing cost-efficient honeycomb core made of recycled PET. In comparison to the PP-core the RPET-core has outstanding weight specific properties, higher service temperature stability and excellent compatibility with all resins and manufacturing methods for composite sandwich constructions. This makes the RPET core interesting for furniture producer. The RPET core is a fully environmentally friendly alternative and has much better shear and compression strength properties than other core materials e.g. PET foam cores.

The systematic search for new applications for honeycomb technology is the basis of the ThermHex success. This results in new material combinations, collaborations and sales markets. Over the last decade, more and more product variants with different core thicknesses and cell sizes have been developed. Sandwich components with ThermHex honeycomb cores are used in many sectors where superior mechanical performance, resistance to chemicals and water is required.

ThermHex polypropylene (PP) honeycomb cores today replace foam, paper honeycombs or solid materials such as pressboard (HDF) or wood.

This article was published by JEC-Group.