INNOVATIVE AND VERSATILE: THERMHEX HONEYCOMB CORES ARE EVERYWHERE

Honeycomb Cores for All Industries – Polypropylene honeycomb cores made by ThermHex Waben GmbH are omnipresent. Due to the unique in-line production process, a particularly cost-efficient production is enabled and therefor the honeycomb cores expand internationally from one application to another. But in order to drive this evolution forward, a strong innovative mindset is necessary.

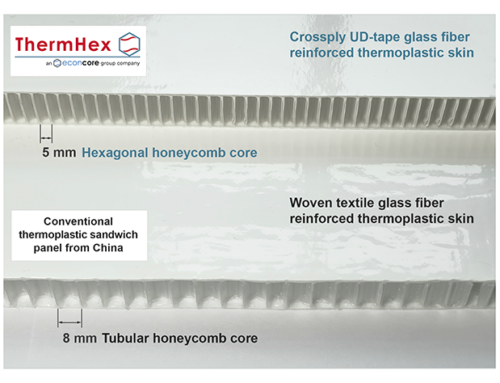

The honeycomb core specialist from Germany offers producers of lightweight sandwich elements a completely different type of the established polypropylene honeycomb core: Due to the worldwide patented, continuous in-line production process, sandwich elements with ThermHex honeycomb cores can be produced very cost-effectively. Furthermore, the honeycomb cores can be thermoformed and are recyclable. They are used wherever high-quality products with particularly high bending stiffness but low weight are required. For example, in truck side walls, automotive interior parts, ship interior construction, pool construction, wind power plants, furniture construction and many other areas.

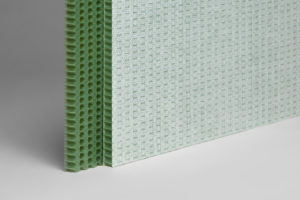

ThermHex has developed a wide range of honeycomb cores for these and other applications: They vary in core height, cell size and density. The skin layers differ depending on the requested properties and on further processing by OEM customers and application areas. This is why the team led by CEO Dr. Jochen Pflug regularly develops innovative products. ThermHex is launching its new “RPET honeycomb core” (Recycled PET) this year. You can already tell by the green outside what is at the heart of the new, highly eco-friendly product variation: With the RPET honeycomb core, customers have the opportunity to include environmental aspects in their purchasing decision. Interested customers will be able to purchase the “green” RPET honeycomb core in the same product variations as the established polypropylene honeycomb core.

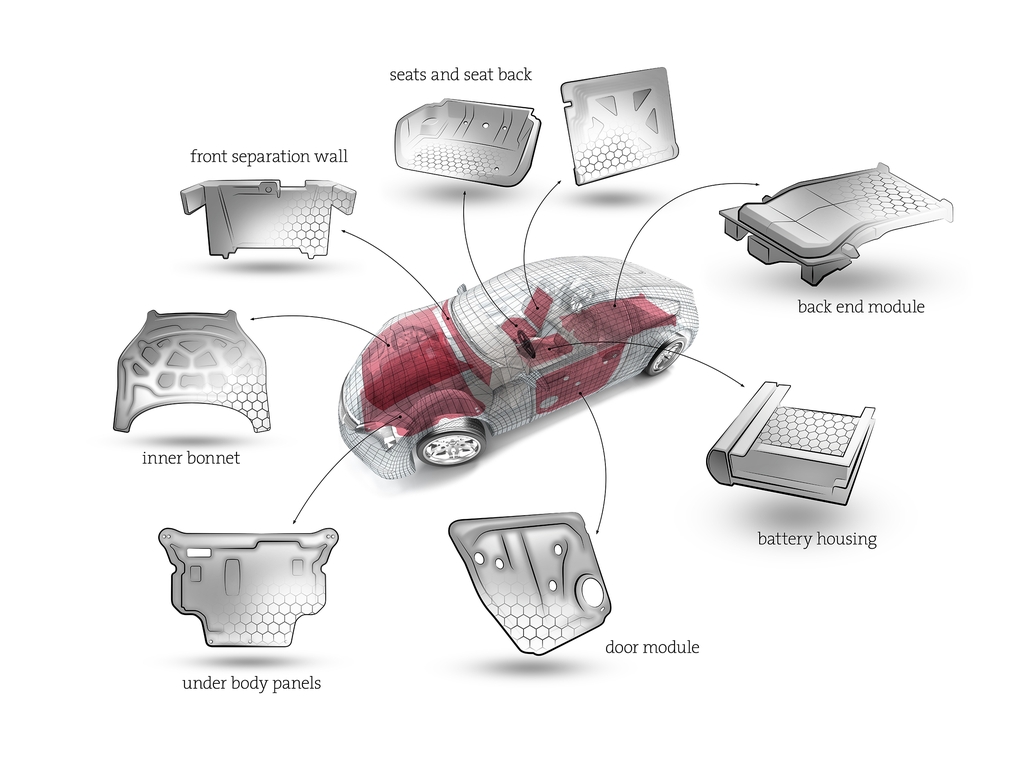

The “Organosandwich” is also new in the company’s product range. It is a true all-rounder, especially for the automotive industry: The thermoplastic material can be used in a wide range of applications in vehicles – from luggage floor, underbody panels and inner bonnet to door modules or battery housing. The Organosandwich is the first sandwich product that ThermHex produces in one integrated in-line process and consists of a polypropylene honeycomb core with two skin layers of glass-fiber reinforced polypropylene UD tapes. The Organosandwich can also be thermoformed and functionalized by injection molding. ThermHex is already working with several tier one suppliers on various automotive parts.

Innovations, research and development are bearing fruit: ThermHex has been on a growth course for ten years. The last business quarter was the most successful in the company’s history. ThermHex is now looking for additional personnel for the production, R&D and sales department.

Multiple application possiblities of the Organosandwich

ThermHex-RPET-Honeycomb-Cores

https://azl-aachen-gmbh.de/de/newslight-14-thermhex/