ThermHex Waben, based in Halle, Germany, produces polypropylene (PP) honeycomb cores as core material for sandwich panels and lightweight components. They offer their customers high quality honeycomb cores which help to produce better and more economic lightweight sandwich panels and parts for different applications.

Thermhex’s engineers work with their clients to develop structural products which achieve greater weight reductions and more efficient usage of natural resources. Overall, the aim is to reduce environmental impact and contribute to sustainability.

The company sells the honeycomb cores globally through a network of distributors.

Easy Engineering: What are the main application areas of your products?

THERMHEX: Thermhex’s honeycomb sandwich components are used in many industries where superior mechanical performance such as mechanical strength, resistance to chemicals and water plus flexibility of use are required.

This covers many composites markets and product applications, including marine (boats, yachts and ships), transportation and automotive (buses, trucks, cars, camper vans and caravans), building and construction (swimming pools and furniture) and other sectors such as renewables and energy.

E.E: What’s the news for 2021 about new products?

THERMHEX: The news for 2021 is a further growth with a focus on sustainable growth and reduction of CO2 emissions. We grew by 12% last year even in a highly turbulent economy.

This year our customers will find even more uses for our polypropylene cores and will increase their sales as their products improve thanks to our technology. And we expect new applications and new products to contribute to this increase.

E.E: What are the ranges of products?

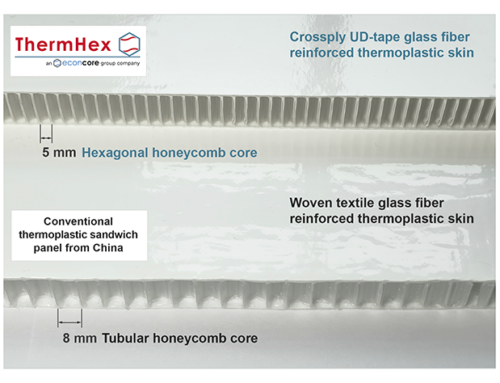

THERMHEX: Our two main product sectors are polypropylene honeycomb cores and the Organosandwich. We offer our cores in densities from 60kg/m³ to 120kg/m³, core thicknesses between 3.5mm and 30mm and cell sizes from 3mm to 9.6mm. Due to the patented continuous production process we are able to produce the core theoretically in endless length and 1.20m in width. The Organosandwich is a semi-finished thermoplastic sandwich panel with PP honeycomb core and glass fiber/PP-skins which delivers a weight saving of up to 80% compared to monolithic glass fiber/PP composite materials. As the Organosandwich is also produced in-line and continuously also this sandwich can be produced theoretically in endless length.

E.E: At what stage is the market where you are currently active?

THERMHEX: We are most active in automotive and transportation, those industries have a huge appetite for the benefits our honeycomb can achieve. However even in these industries our technology is at an early stage.

E.E: What can you tell us about market trends?

THERMHEX: The market of sustainable lightweight materials is on an upward curve with no end in sight. The properties of our honeycomb is addressing the sustainability and environmental movement which is important in guaranteeing the safety of our world in the future. If you strip a kilo gramme of weight out of a vehicle, the environmental benefits are clear.

E.E: What are the most innovative products marketed?

THERMHEX: The key innovation of our ThermHex honeycomb core is not in one specific application. The key is our unique and patented production process. Honeycomb cores are usually extruded and cut from the block. This results in high production costs, which had in the past limited the application of honeycomb materials to weight sensitive markets like aerospace. The ThermHex production process minimizes the costs and resources required to produce the honeycomb cores, as production takes place in a single production line. Thus, for the first time, honeycomb cores can be produced in high quantities at low cost and in an environmentally friendly way.

Thanks to the high degree of automation, the application of cover layers can also be integrated into this production. In addition to the PP honeycomb cores, ThermHex offers a composite sandwich material with a glass fiber/PP cover layer called Organosandwich. This latest product is in high demand, especially in the automotive sector.

E.E: What estimations do you have for 2021?

THERMHEX: ThermHex expects a further increase in demand for the honeycomb cores, as well as greater demand for the Organosandwich. As a supplier to the automotive industry, ThermHex will acquire necessary certificates to be able to supply even more OEM’s. The construction of a second production plant is planned in order to be able to react to increasing demand from the market.

Read the original article here: https://easyengineering.eu/interview-with-thermhex-waben/