Honeycomb panels “from a single source” reduce weight and costs

Plastic honeycombs for lightweight construction are traditionally manufactured in blocks and then cut from block to plate. This is complex and too expensive for many applications. ThermHex honeycomb cores, on the other hand, are created in a patented in-line process. In addition to material and weight advantages, the process brings considerable cost savings. At the same time, it forms the basis for numerous further research and development projects.

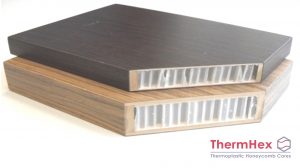

ThermHex honeycomb cores made of polypropylene (PP) are now replacing foam, paper honeycombs or solid materials such as pressboard (HDF) or wood. Since the start of production in 2010, the honeycomb panels have proven themselves in furniture, motor vehicles, boats and swimming pools. They can also show off their advantages in scaffolding, trade fair construction or for theater or film sets.

Typical example from furniture

The potential of the technology can be illustrated in the following application example, which resulted from a development cooperation.

A 19 mm thick chipboard with CPL top layer and ABS edge protection was replaced by a sandwich consisting of a 15 mm PP honeycomb core, two two mm HDF top layers as well as CPL top layers and ABS edge protection (see figure ). The HDF top layers and PP honeycomb core were bonded using moisture-resistant D3 dispersion glue. The CPL top layers and the ABS edge protection were applied using standard methods in practice.

Countable advantages for processors and end customers

The advantage of the ThermHex honeycomb core board is clear: it weighs only half of the solid particle board – with identical load capacity. It is much cheaper to manufacture, cheaper to transport and easier to use when setting up. On top of that, it has better weather resistance (e.g. moisture resistance) compared to wood-based materials or paper honeycombs. Among other things, this is advantageous for furniture in outdoor and wet areas.

The PP sandwich panel shown is usually used in cupboards, shelves or as a table top. For commercial furniture, bathroom and kitchen equipment and articles in the growing area of the takeaway markets, solid particle boards can be excellently replaced by the sandwich composite.

The unique and continuous in-line process for the production of ThermHex honeycombs enables efficient production. The usual intermediate steps, such as. B. cutting off the block or assembling honeycomb rows are not required. This ensures an enormous reduction in costs. On top of that, material residues arising during production are immediately and completely returned to the production cycle.

Further development for the aviation industry

ThermHex invests continuously in research and development and cooperates closely with partners from a wide range of economic sectors. For example, customers are currently working on the development of a high-performance honeycomb core for use in aircraft. The goal is the continuous and cost-effective production of honeycomb panels that meet the strict requirements of the aviation industry, for example with regard to fire risk, smoke development and toxicity (fire, smoke, toxicity / FST). Honeycomb cores made of high-temperature thermoplastics or thermoset polymers meet the required fire protection requirements, whereas uncoated honeycomb cores made of polypropylene are more suitable for other applications.

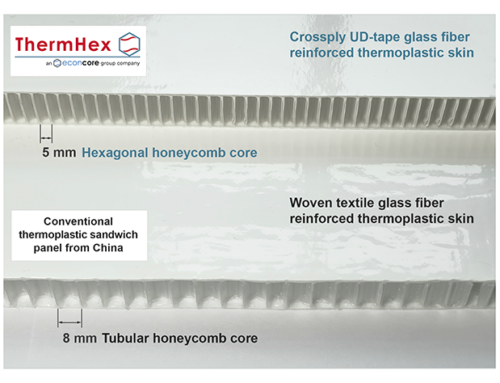

Cores for rigid injection molded parts

Another project is the development of a thermoplastic organic sandwich semi-finished product with Fraunhofer IMWS in Halle. The aim is to manufacture a semi-finished product from PP honeycomb cores with UD tape glass fiber reinforced PP top layers in a continuous in-line production. These organic sandwich semi-finished products are then processed in plastic injection molding into functionally integrated complex sandwich components. As a result, injection molding components for the automotive industry with previously unattainable bending stiffness can be produced in large quantities in very short cycle times. Here the weight reduction in combination with a cost reduction is of enormous advantage.

The production of honeycomb cores with other thermoplastic materials is possible, and research and development continues here as well. The ThermHex parent company EconCore in Leuven, Belgium is responsible for this.

Innovation as the basis of success

In the past, the targeted search for new fields of application for honeycomb technology helped ThermHex to report the highest sales in its eight-year company history in the past financial year 2016/17. Sales of propylene honeycomb cores increased by 15 percent compared to the previous year.