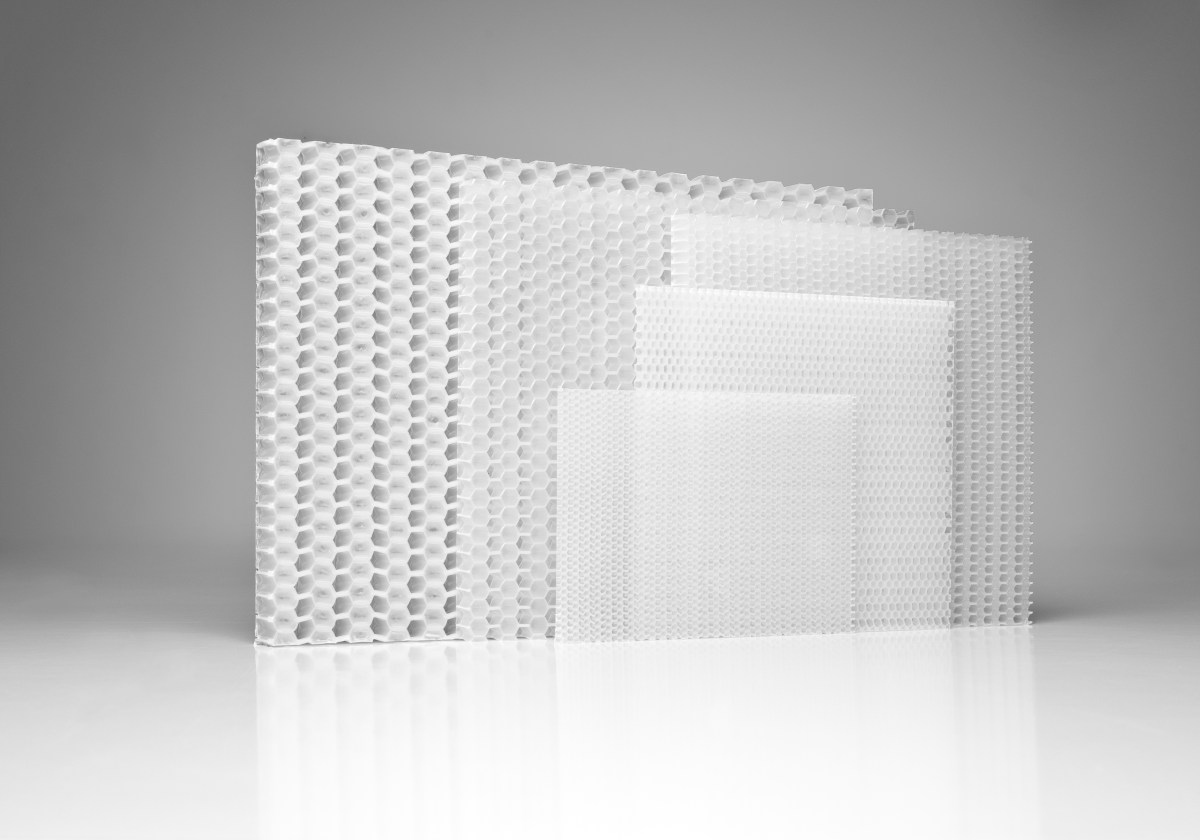

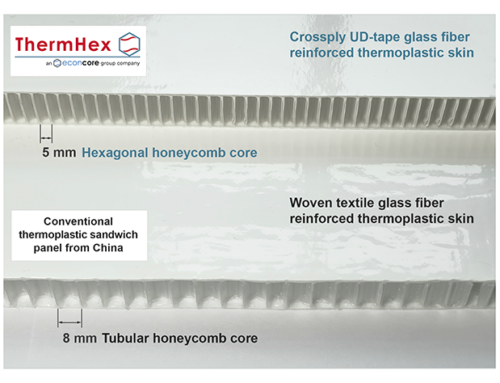

ThermHex produces its PP honeycomb cores with a new vacuum forming roll that enables a cell width of 5 mm at a cell height of 11 mm to 12.7 mm. With this product innovation, the honeycomb core specialist increases resource and cost efficiency and achieves higher production capacity. In addition, the material properties open up new application possibilities for the PP honeycomb cores. ThermHex will present the latest range of innovative polypropylene honeycomb cores at Birmingham’s Advanced Engineering from 1st to 2nd November in Hall 3A, Stand J92. Visitors can convince themselves of the high-quality honeycomb panels and their diverse applications.

“With conventional production processes, PP honeycomb cores with such small cell widths have so far only been available for aerospace applications,” explains ThermHex Managing Director Jochen Pflug. “These procedures are more costly than ours. That’s why we see great potential for the new product variants and are pleased to be able to introduce them to the specialist audience at Advanced Engineering. “The smaller cell size results in optimization potential and further options for users. For example, the new PP honeycomb cores can be used as an alternative to foam cores or resin-impregnated nonwoven core mats. The new roll geometry also produces an improved surface structure. Cost savings are possible through lower material costs and a faster production process.

“In order to be able to offer our customers new applications for PP honeycomb cores, we rely on research and development. The new product variants are in high demand and enable users to achieve further cost savings, “says Jochen Pflug.

The Advanced Engineering exhibition takes place at the National Exhibition Center in Birmingham (UK). It is the largest annual meeting of advanced engineering professionals, connecting the entire supply chain of British industry with research and development, design, testing, production and sourcing of OEMs and leading industrial companies. At booth J92, ThermHex informs interested trade fair visitors about the worldwide unique, patented and continuous production process as well as about existing and future product variants. The extremely resource-saving and cost-saving production of ThermHex honeycomb cores ensures extremely economical production of sandwich components for, among other things, truck body superstructures, ship interior fittings, modern swimming pools and much more.

“The Advanced Engineering is an important date for us. Here we have the opportunity to make international contacts and open up new business opportunities in the UK market, “says ThermHex Operations Manager Jana Heinrich, looking forward to talking to the trade audience. By participating in the UK Fair, ThermHex promotes its worldwide distribution.