The location of the new logistics site in Halberstadt for the worldwide supply of spare parts for Daimler trucks is very welcome news for the region. The company attaches particular importance to ecological aspects such as solar cells to supply the site.

The focus is also increasingly on more environmentally friendly aspects when it comes to the materials and construction methods of commercial vehicles, and here, too, Daimler Truck is investing in Saxony-Anhalt. Daimler Truck AG has already been working with ThermHex Waben GmbH since 2020 on the development of special sandwich materials and components (metal-plastic hybrid) in a joint project with ElringKlinger AG, Edevis GmbH and the Fraunhofer Institute for Microstructure of Materials and Systems IMWS in Halle.

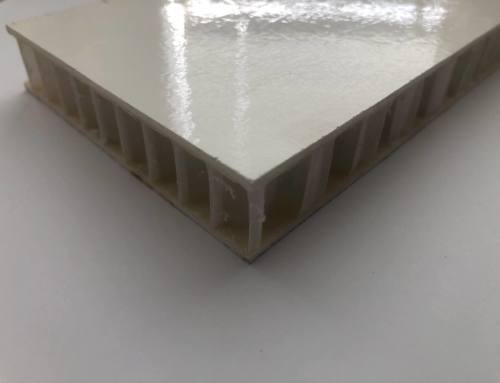

Briefly explained: The sandwich materials EconCore and ThermHex Waben GmbH have developed with a lightweight honeycomb support core enable particularly high-performance and cost-efficient lightweight solutions. Weight savings of up to 80 percent can be achieved. What’s more, these materials are particularly sustainable because they can be recycled.

In collaboration with the Fraunhofer Institute for Microstructure of Materials and Systems IMWS Halle, large-scale production solutions are being developed for our cost-efficient and resource-saving materials.

“We have now achieved a leading position in Saxony-Anhalt with the development of our innovative lightweight materials” resumes Dr. Ing. Jochen Pflug, Managing Director of ThermHex and EconCore.

More information about the joint project can be found here: https://www.imws.fraunhofer.de/en/presse/pressemitteilungen/efficient-sandwich-lightweight-structures-with-high-surface-qual.html