The composite-sandwich industry experts met in Halle: around 100 participants from the USA, England, the Netherlands, Belgium, Russia, Israel, Switzerland, Luxembourg, Denmark and Germany accepted the invitation from ThermHex Waben GmbH and Fraunhofer IMWS for the first Composite-Sandwich Conference. This was followed by two days full of input with guided company tours, an evening event in a festive atmosphere as well as a concentrated load of presentations and a lot of networking among experts in the fiber composite sandwich industry.

The first day of the conference started at ThermHex. The participants took advantage of the offer to visit the production plant of ThermHex Waben GmbH and the pilot plant center of Fraunhofer IMWS. Divided into groups, the participants experienced first-hand the continuous production of the thermoplastic honeycomb core and the forming and injection molding process at the pilot plant center of the IMWS in Schkopau.

The National Academy of Sciences, Leopoldina, whose scientists themselves advise the German federal government, was the setting for the evening event that followed. The Vice President of the Leopoldina, Prof. Dr. Dr. Gunnar Berg welcomed the participants and gave a brief insight into the history of the house. Professor Christian Berggreen from TU Denmark gave a keynote speech on dis- and debonds in sandwich structures – past and present. During the subsequent 4-course menu and musical accompaniment by the Halle band “Kitchen Radio”, the participants had time to network.

On the second day of the conference, the participants heard 14 lectures, which were thematically divided into three blocks. In the subject area “Industrial Applications”, Dr. Mikhail Levit from DuPont Safety and Construction said something about “past, present and future of Nomex® based and Kevlar® based honeycomb cores in aircraft applications”. The companies Airborne, Diehl Aviation and Cotesa gave exciting insights and an overview of the areas of application and requirements for sandwich materials and manufacturing processes in the aerospace industry.

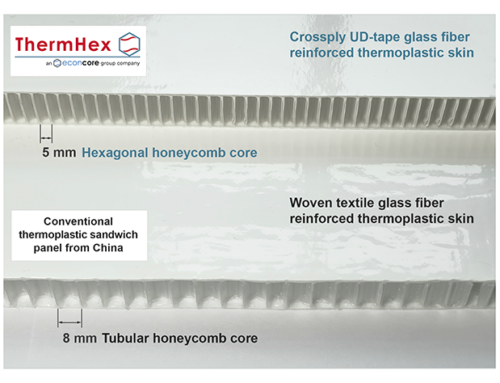

The second topic block dealt with material properties and developments of composite sandwich structures. Experts from Fraunhofer IMWS, the Institute for Lightweight Construction and Plastics Technology Dresden, FITS Technology, EconCore and TU Dresden gave lectures on high-performance thermoplastics, complex sandwich structures with foam cores, their mass production and the simulation of honeycomb cores in sandwich structures.

After the lunch break we continued with block number three and the insight into technologies and production techniques in the composite sandwich industry. Vehicle concepts from the German Aerospace Center were presented, there was an overview of sandwich technology at the plastics center in Leipzig, the development project for the new hierarchical sandwich honeycomb cores from EconCore / ThermHex, thermoplastic sandwich structures with bead foam cores from the New Materials Bayreuth and the possibility of industrial mass production of continuously produced composite sandwich structures with honeycomb cores by Fraunhofer IMWS.

The participants did not expect so much different and application-related input and gave consistently positive feedback. The deep insights into the world of sandwich structures, their applications and processing, as well as the exchange among experts made the conference a huge success.

“The fact that so many participants came from abroad shows that we hit the nerve with the Composite-Sandwich Conference. There are many lightweight construction conferences, but the Composite-Sandwich Conference on industrial applications, production processes and materials for sandwich structures is unique. We will now hold this conference regularly,”summarizes Dr. Jochen Pflug, Managing Director of ThermHex Waben GmbH and co-organizer of the event and with this statement corresponds to the wishes of the participants.

Further information: www.faserverbund-sandwich.de/en/home/