Composite Sandwich Conference

Sandwich construction using fiber-reinforced plastics enables highly efficient lightweight structures for a wide range of applications. For the first time, on February 5 and 6, 2020, a conference in Halle (Saale) will be specifically dedicated to this subject and will elucidate trends in development of materials and production techniques. The ThermHex Waben GmbH is one of the organizers. In the following interview, the company’s CEO, Dr.-Ing. Jochen Pflug, explains the motivation for a composite sandwich conference; he also points out the reasons why an extended use of sandwich technology is not only beneficial for the aviation and aerospace sectors, but also for the automotive industry and many others.

What do fiber-reinforced sandwich structures enable that other approaches for lightweight construction do not?

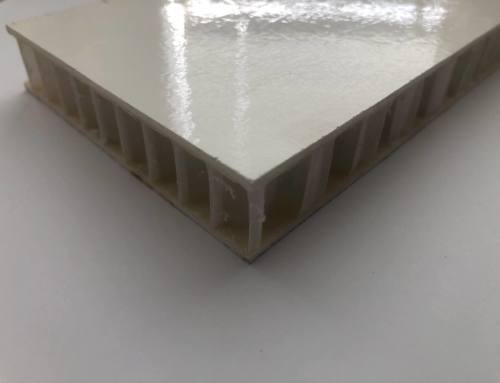

Dr. Jochen Pflug: Lightweight construction with fiber-reinforced plastics is an established technique to reduce weight and thus fuel consumption. Sandwich construction enables additional to the weight saving potential also lower material costs and production costs since the expensive fiber composite materials are only used for the thin top layers of the parts. Furthermore, advanced production techniques make it possible to produce fiber composite sandwich structures in high volume at low cost.

What markets can benefit from a wider use of sandwich technology?

Dr. Jochen Pflug: These are the markets that mostly have not yet relied on fiber composite sandwich construction due to high costs. Awareness of the cost efficiency that can be achieved with sandwich materials is not yet widespread. I see great potential here, since lightweight design is becoming more important altogether. This is the case not only in the automotive industry with components like the trunk floor, underbody panels and battery housings, but also in the construction industry with new solutions for scaffolds, sheetings for concrete casting and facing elements. Even the aviation and aerospace industries, pioneers in the use of fiber composite structures, can find additional potential for sandwich constructions thanks to new materials and production techniques.

What are the current challenges for sandwich technology?

Dr. Jochen Pflug: In many businesses that have made use of fiber composite sandwich panels, we have already reached quantities in which efficient, automated production principles are becoming more and more important. In the aviation and aerospace sectors alone, the traditional production methods are currently being reviewed in order to produce larger quantities at lower costs. Another key issue – in the industry and during our conference in Halle as well – is that of thermoplastic fiber composite sandwich structures. It is a real challenge to reach the weight-specific properties of the thermoset solu-tions by means of thermoplastic materials, but there exist exciting approaches both in research and development. I hope our conference can contribute to highlight solutions for this challenge, since our two most important target groups may enormously benefit from interactions in this mutual exchange. The aviation and aerospace industries are rich in experience of the lightweight potential and material characteristics of fiber composite sandwich constructions, whereas the automotive industry has huge expertise in efficient production techniques. This is an ideal combination.

There is no lack of workshops and business meetings on lightweight design. Where do you see the additional value of the new conference?

Dr. Jochen Pflug: The focus on sandwich construction in which we bring together internationally leading experts is our unique selling point. And for a conference like this, Halle in Saxony Anhalt is also the best location, because the first expanded honeycomb cores and the first sandwich structures for aerospace were produced here. Together with the Fraunhofer Institute for Microstructure of Materials and Systems IMWS, the co-organizer of the conference to be held on February 5 and 6, 2020, and the plastics center SKZ, we provide comprehensive know-how on this subject in the region. Its focus on application makes the event very special. Unlike scientific conferences, such as the International Con-ference on Sandwich Structures ICSS, we unambiguously focus on the needs of industry and future-oriented solutions for companies.

https://composite-sandwich.com