Pioneering Innovations in Series or Completely Customized

Composites from the Heart of Germany

PANEELtec GmbH is a medium-sized company from Thuringia, Germany and is constantly looking for new solutions for future-oriented innovations in the field of sandwich panels. Their products are produced in large series, but can also be individually tailored to customers’ needs. Sandwich panels from PANEELtec are used as composite elements in technical applications (e.g. for ventilation ducts of railway wagons), for door panels, as cladding elements of machines and plants and also as bodies of commercial vehicles or for trailer and caravan construction. The products of PANEELtec are outstanding for their very high mechanical properties.

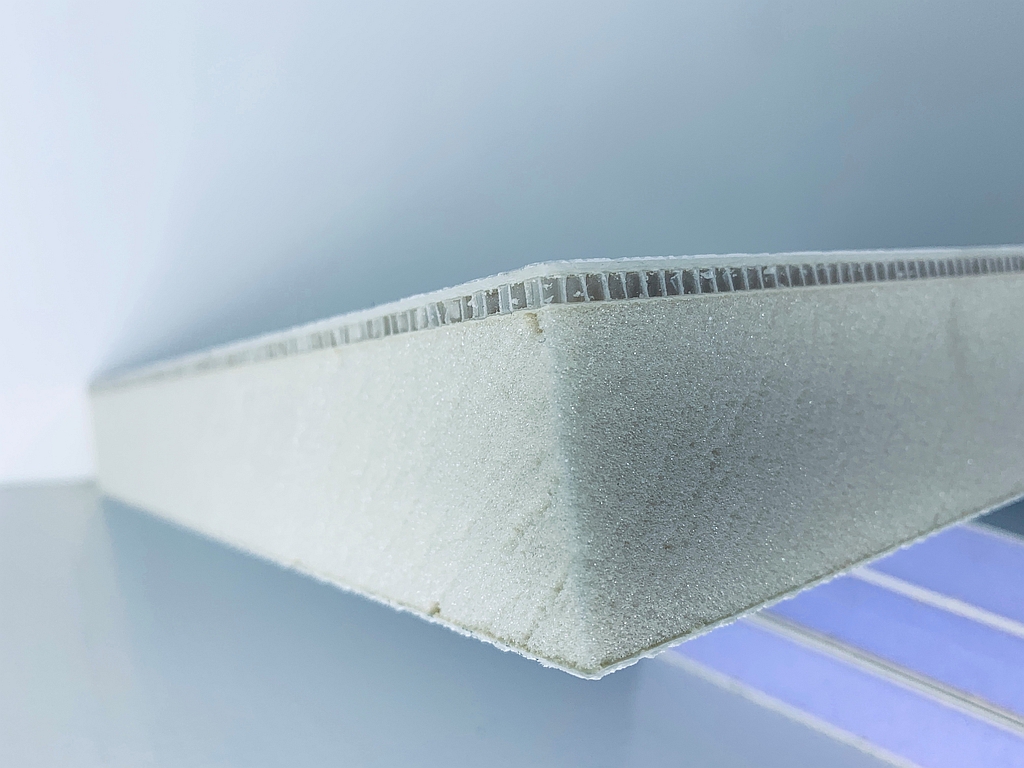

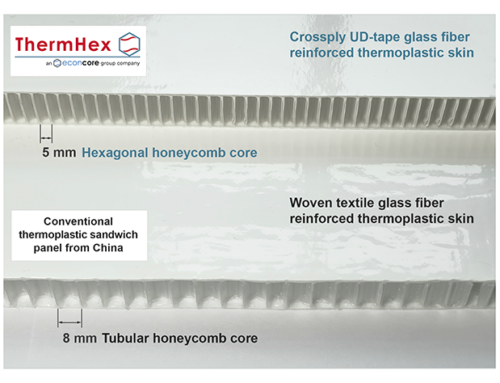

Lighter, Thinner, Stronger – with ThermHex Honeycomb Core

With ThermHex honeycomb cores PANEELtec found a new and lighter solution for its sandwich panels in 2013. ThermHex polypropylene honeycomb cores are used in sandwich composites with PU foam under the name “DuoCore” and with PU foam and ImpactShield SL Bond composite panel under the name “TripleCore”. In addition, PANEELtec also offers ThermHex honeycomb cores as a pure panel with a GRP top layer on both sides. The composite products with honeycomb core are known for their very high mechanical strength – but have a much lower weight than panels with a solid material core. The ThermHex honeycomb core is processed by vacuum bonding. Bonding is done with 2K-PUR adhesive – with curing on a vacuum table.

Panels with Honeycomb Core are Right on Trend

With the use of ThermHex honeycomb cores made of polypropylene, PANEELtec picked up the lightweight construction trend in the industry at an early stage. The adapted products show that panels with a honeycomb core are just as strong as or even stronger than composites with a solid material core. There are many advantages from the weight reduction: Less dead weight means more loading capacity. The energy consumption of vehicles equipped with lightweight bodies or other lightweight applications is also reduced. The top layers could be made thinner and also B2C customers of PANEELtec benefit from easier processing of the panels due to their light weight.

https://www.paneeltec.de/wordpress/