ThermHex Waben, producer of polypropylene honeycomb cores and the Fraunhofer Institute for Microstructure of Materials and Systems IMWS, both based in Halle, are collaborating for many years and have conducted several research and development projects. The collaborative effort is focused on the development of production and processing technology for series production of honeycomb cores and the Organosandwich.

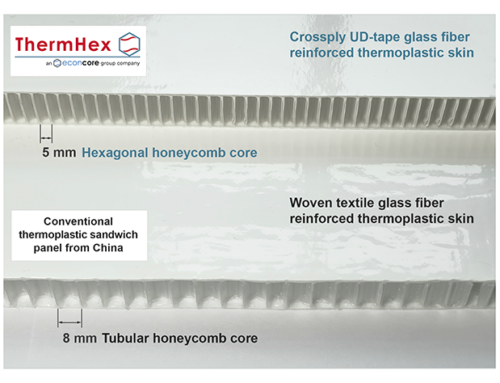

The Organosandwich, a semi-finished product, consists of two very thin face sheets of thermoplastic fiber composites (organosheets) which are separated by a thermoplastic honeycomb core. It provides high stiffness at minimal weight, but without additional ribs for stiffening.

These semi-finished products become particularly cost-efficient when applied in-line to the honeycomb core in a continuous process and bonded to it. In subsequent production steps, they are further processed into components, e. g. thermoformed and functionalized by injection moulding within very short cycle times. The corresponding component production technology was developed by Fraunhofer IMWS under the brand name TS-moulding.

The technology developed as the outcome of this research will contribute to ThermHex’s highly automated production process and enable the company to meet their targets of a total sales volume of 1 million kilograms of Organosandwich and honeycomb cores for this year, and a further annual growth of 10-20% in years to come.

The ThermHex process, patented by EconCore NV in Belgium, enables thermoplastic honeycomb cores to be produced in continuous in-line production. After extrusion, the web is rotationally vacuum-formed, folded, laminated and cut to the length desired by the customer. In traditional processes, every layer of honeycomb must be cut individually from a block and then laminated.

This makes the conventional production methods for honeycomb cores both complex and expensive – with ThermHex, all production steps take place on a single production line. The process is more resource-efficient and significantly less expensive than conventional honeycomb core manufacturing processes.

At the production facility in Halle, honeycomb cores with a thickness of 3 to 30 mm and very small cell sizes for better surface qualities and an individual length of up to 6 meters can be produced.

The honeycomb cores are processed in particular by the fiber-composite industry into sandwich panels and components, which are used e. g. in truck bodies, in automotive interior or in prefabricated bathrooms and swimming pools.

A sandwich construction permits an enormous potential for saving weight. By using a lightweight core material that keeps two thin face layers apart, weight savings of more than 80% are possible compared with a monolithic construction. In addition to the weight savings, significant material cost savings are also possible.

Only ThermHex’s process of honeycomb production on a single production line can enable the cost-efficient, continuous production of Organosandwich semi-finished products.

Mona Boche-Würfel, the marketing and communications manager at ThermHex said: “This collaboration between ThermHex and Fraunhofer IMWS will provide industry leading changes to honeycomb technology. The technology that will be developed through the exciting collaboration will enable the mass production of almost CO2-neutral sandwich panels within very short cycle times as part of a highly cost-efficient process.”

ThermHex polypropylene honeycomb cores with thermoplastic top layers are used in the automotive industry, e. g. for the trunk floor of the Maserati Ghibli and the Jaguar F-Type or the trunk cover of the Toyota Prius PHV.

The Organosandwich joint research project from ThermHex Waben and Fraunhofer IMWS was funded within the EFRE program by the European Union via Investitionsbank Saxony-Anhalt.